Documentation

Get advice on the product you need from our team

We are looking for new products

We help you to find the new raw materials you need for your processes, with the required quality and in the most competitive situation possible. We save your technical and management departments time and effort.

Wide range of products and solutions

At Barcelonesa, we have a wide range of products and solutions and we have the capacity to make our own packaging and customized maquilas.

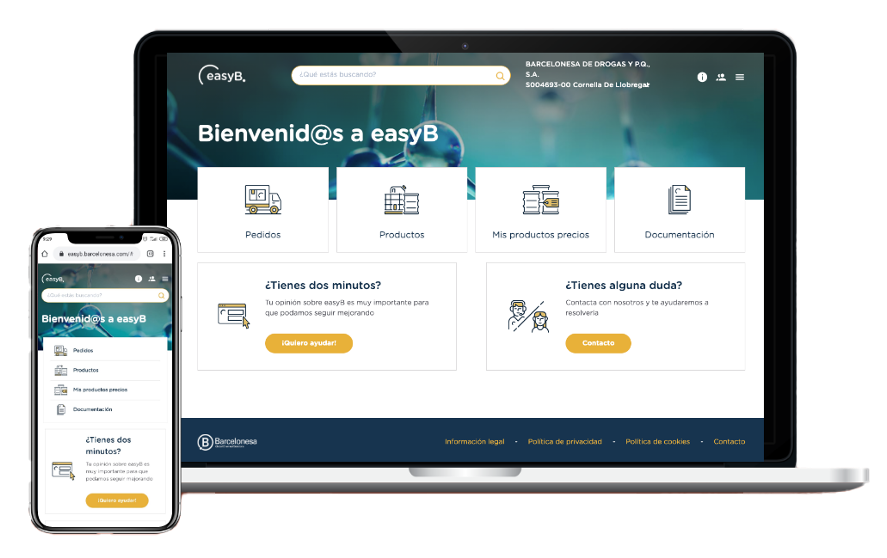

easyB: Technology at your service

We want you to spend your time on what's really important. That's why we have designed easyB; our online platform where you can easily manage your orders, consult/download all the documentation you need and consult our product portfolio.

Looking for a specific product?

Through our easyB platform, you can see all the products we have available, download documentation and much more.

Quality

Certifications that guarantee that we comply with the highest quality standards in terms of products, services and management.

How can I help you?

Jordi Pérez

Sector Manager